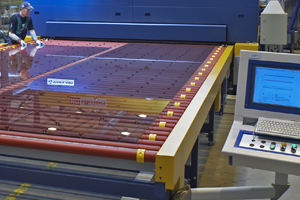

The tempering of flat glass is achieved by heating and then quenching in either conveyorized or oscillating furnaces. The process is generally conducted in two separate chambers with the quenching being achieved using very high volume airflow. This can be a high volume, low mix, or low mix, high volume application.

Application Need

During tempering, glass is heated to a point where it becomes soft; however any overheating will increase distortions in the glass. Setting up the process for different thicknesses of glass is a time-consuming, trial and error process. The heating of low emissivity glass can be difficult, as it is designed to reflect the infrared component of the heat energy. An accurate method of measuring glass temperature is required to set up and then continually monitor the process.

Benefits to the customer

Record the thermal image of every glass sheet produced - certify every product treated

Detect immediately any change in thermal performance - minimize downtime and scrap

Quickly see the effect of changing furnace settings, resulting in faster process setup

Obtain the full 'entry to exit' profile, enabling optimization of heating and cooling process

Thermal Profiling Systems

Thermal Profiling Systems

Contact: Yang Wanlu

Phone: 18257343661

Tel:

Email: dobeny@126.com

Add: Zheshang Mansion, No.8 Jingdu 3rd Road, Zhejiang Haining Jingbian Industrial Park, Haining, Jiaxing,Zhejiang