DoBeny's new miniature, low cost,high performancemolten steel Infrared temperature sensor.

· non-contact

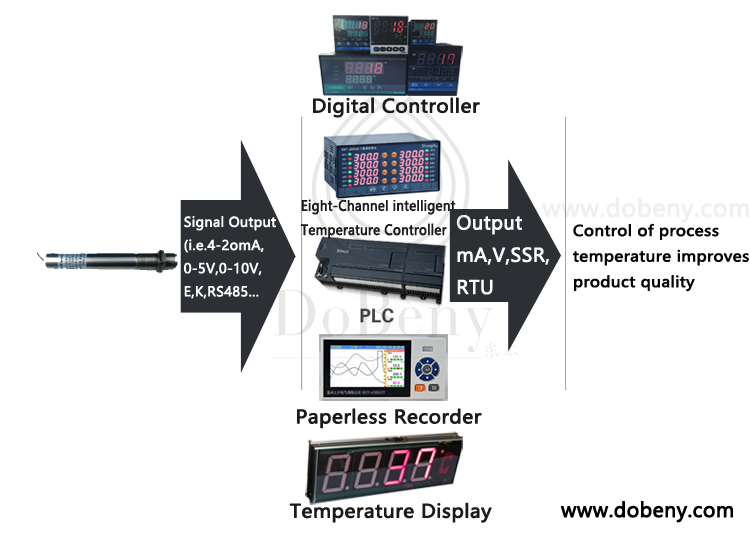

· Output: 4 to 20 mA

· interface directly to most of all meters, controllers, dataloggers

· Fast Response 5ms with High Stability

· Optional Air/Water Cooled Housing, Air Purge Collar, Laser Sighting Tool and Mounting Brackets

General Specifications

Model:IRT-2600A

Temperature Range: 400~2600℃

Supply Voltage: 24 VDC

Output: 4 to 20 mA

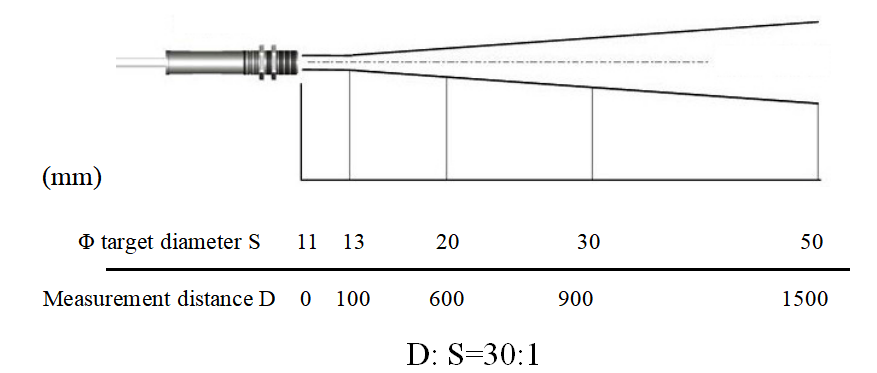

Field of View: 30:1

Accuracy: ±1%(when environment temperature is 23±5℃)*

Repeatability: ±1%

Response Time: 5ms

Spectral Range: 0.1-18μm

Construction: Stainless Steel 304

Dimensions: ø18 x length107 mm

Mounting: two mounting nuts

Cable Length: 2m as standard (custom lengths also available)

Weight: 400g with 2 m(7') cable

Environmental Rating: IP65

Ambient Temperature Operating Range: 0 to 50°C (32 to 122°F)

4-wire , 3-wire or 2-wire

The Infrared Temperature Sensor can calculate the surface temperature of an object by measuring intensity of infrared radiation emitted by target without any contact with the target. Non-contact temperature measurement is the greatest advantage of Infrared Temperature Sensor which allows user to easily measure temperature of target which is difficult to approach or is moving.

Series H Infrared Temperature Sensor is an integrated device which integrating sensor, optical system and electronic circuit inside a stainless steel shell; series H is easy to install, standard thread on its metal shell can easily connect with installation part; meanwhile, series H has various types of components for selection (including blower, installation support, adjustable installation support and blower protection jacket) to meet requirements of different work conditions.

Maximum distance and size of measurement point

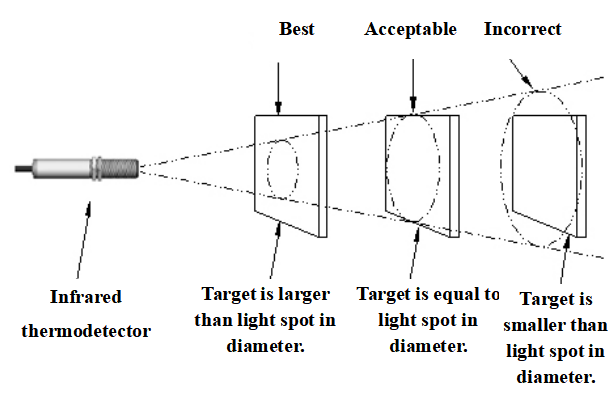

Size of measurement target and optical features of infrared thermodetector determine maximum distance between measurement target and measurement head. To prevent measurement error, the measurement target should fill field of view of probe as much as possible. Therefore, always keep measurement point smaller than measurement object or at least the same size as measurement target.

When adjust measurement target and measurement head, ensure that optical path is barrier free, as shown below:

Technical Experts at Your Service Call 86-18257343661 from 8 AM—5 PM China for applications and technical support, or email dobeny@126.com, you will have a response within 24 hours.

Contact: Yang Wanlu

Phone: 18257343661

Tel:

Email: dobeny@126.com

Add: Zheshang Mansion, No.8 Jingdu 3rd Road, Zhejiang Haining Jingbian Industrial Park, Haining, Jiaxing,Zhejiang